A wood burning stove helps to enhance the efficiency and thermal output of wood when used with open fires in your house. While a typical fireplace can have an efficient capacity of around 20 percent, wood combustion can achieve an efficiency of about 80 percent, which is far more heat than the fireplace lost in your home.

So What Are The Parts Of A Wood Burning Stove?

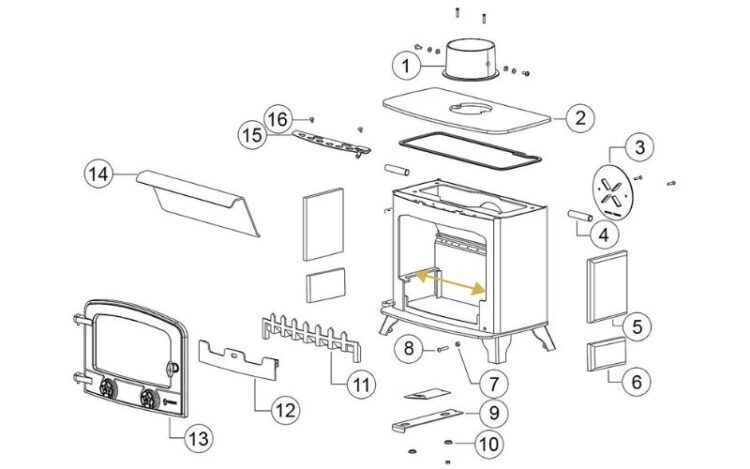

Each type of wood-burning stove has a distinct design and construction, but in general, the furnace is made up of the same principle parts to extract the greatest heat from burning wood.

5 Essential Parts Of A Wood Burning Stove

Firebox

The firebox is the principal element of the wood stove, where the fire is built, and more logs are placed during the fire. This is the space through which you see the brass burning and the flames flashing through the glass door.

Other components for wood burning stoves or a metal grating in a multi-combustion furnace can be found in the base of the firebox. The flutter, with the flue collar immediately behind, lies at the top of the firebox.

Baffles

The outlets of the wood-burning stoves lie behind the blanket, which are flats on the top of the stove so that waste gasses are not left too fast by the fire.

By slowing down how fast the gas leaves the stove, the secondary burning of the gasses takes longer, so the stove may create more heat.

A baffle also helps reflect and return more heat to the firebox to improve secondary gas burning.

Therefore the hottest section of the stove is placed right above the fire. In addition to a baffle, it needs to cope with high temperatures in the consumption of waste gasses to generate additional heat.

Controls Of Air

Typically, primary and secondary air may be operated by hand using controls in a wood-burning stove, but tertiary air ventilation cannot normally be closed.

When primary and secondary air ventilation is opened or shut manually, you may regulate how fast and efficiently the fire in the fireplace burns the wood. Vents are operated differently in each type of wood stove, and it is thus necessary to study your user manual to learn how to make optimum use of the vents from the combustion of the wood on your specific stove.

Flue Collar

The flue collar sits on top of the fireplace, although generally behind the baffle and on top of the fireplace. The flue collar is where the wood furnace joins the furnace pipe that offers a means to safely depart the residence for fire waste gases.

The flue collar may be positioned on or off the top of the stove depending on the style of the woodstove; depending on the route the flute goes outside your home.

Sealed Doors

Usually, you notice a seal around the edge when you open a wood burning stove door, which prevents any airflow through the side of the door while it’s shut.

You can notice on one of the wood fireplaces that the door of the stove is double scale, and when the door is closed, the ashtray is likewise scale-proof. Only one seal is attached to the other stove.

The seal is generally composed of fiber, fireproof and thermo-resistant fiberglass rope.

The door opening cannot be used well by most wood-burning stoves, and thus the airflow can be regulated easier through the air ventilation.

Other Parts Your Wood Burning Stove May Include

Air Wash

By the front door, almost every new stove has a glass panel. In contrast to earlier designs where the smoke in the firebox can rapidly induce the glass to black, the modern stoves employ an air-wash mechanism to enable the glass to remain clean.

The air washer is an air hole on the top of the glass for combustion. Combustion air is directed on the glass within, minimizing smoke condensation and cleaning the glass.

Ash Pan

A bottom of a fireplace for the collection of ashes, which made the stove easy to clean.

Combustor Catalytic

A ceramic insert passes through several tiny channels or tubes. (It’s like a sweet pee.) Then, a coating of catalytic chemicals, typically platinum or palladium, is applied to the ceramic surface and interacts with smoke that passes through the canal, decreasing the smoke ignition temperature and burning the smoke.

Damper

A damper is a mobile platform that controls the flow of gasses into the oven. The older furnace occasionally had in the pipe a pipe damper, a circular vapor, which the operator shut or opened to decrease or increase flow by the furnace.

Catalytic new stoves in the stove itself feature a bypass damper. This is a metal plate in the stove that permits fumes and vapors, if opened, to bypass the catalytic unit, i.e., travel around. The operator closes the bypass damper when heated to the right temperature for the catalytic unit, which forces the smoke via the catalytic combustion engine.

Secondary Burn Tubes

These are metal tubes in the top of the firebox that permits the air to enter the firebox. Unburned gasses from the fuel load combine and ignite with oxygen. Smoke lost in an old fire is burnt, efficiency is increased, and emissions of smoke are reduced.

Conclusion

By the end of this article, I hope that you have understood the essential parts of a wood-burning stove.

If you want a rustling fire in this winter’s fresh new timber stove, consult professionals to ensure that it’s all correct. Safety is the top consideration, and your system is safe and functioning by a skilled fireplace business.

Make sure your stove is not a wasted investment, and you schedule routine cleaning and inspections of your stove annually according to the manufacturer’s instructions.

Once your wood stove is set up to maintain it, sit back and relax and enjoy the flames!

References: